What are the advantages of PVC whole core elevator belts?

In the realm of industrial conveyance systems, elevator belts play a pivotal role in ensuring the efficient and safe transportation of goods and materials. Among the various types of elevator belts available, PVC whole core elevator belts have emerged as a popular choice due to their unique set of advantages. This comprehensive article aims to delve into the numerous benefits offered by PVC whole core elevator belts, highlighting their significance in modern industrial applications.

I. Enhanced Durability and Longevity

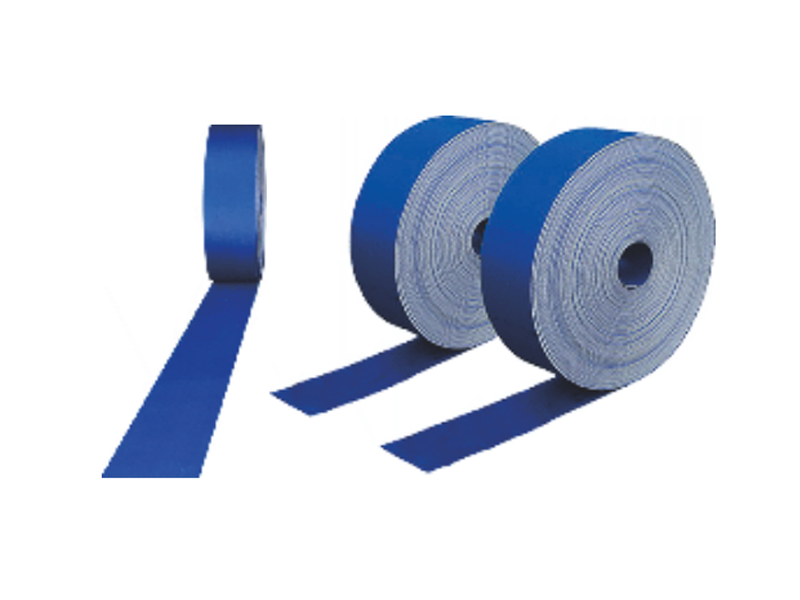

One of the most significant advantages of PVC whole core elevator belts lies in their exceptional durability. Unlike traditional elevator belts that may consist of multiple layers or components, PVC whole core belts are constructed with a solid PVC core. This design eliminates the potential weak points that can arise from the bonding of different layers, resulting in a more robust and reliable conveyor system.

The PVC material itself is known for its excellent resistance to abrasion, tearing, and punctures. This inherent strength ensures that the belt can withstand the rigors of heavy-duty applications, such as mining, construction, and manufacturing, where materials are frequently moved and subjected to significant stress. As a result, PVC whole core elevator belts offer a longer service life compared to other types of belts, reducing the need for frequent replacements and minimizing downtime.

II. Superior Tensile Strength and Load-Bearing Capacity

PVC whole core elevator belts are renowned for their impressive tensile strength and load-bearing capacity. The solid PVC core provides a high level of structural integrity, enabling the belt to handle substantial loads without compromising its shape or performance. This makes them ideal for applications where heavy materials need to be transported vertically or at steep inclines.

Furthermore, the consistent thickness and density of the PVC core ensure uniform distribution of tension across the belt's width. This prevents localized stress concentrations that could lead to premature failure or deformation. As a result, PVC whole core elevator belts can operate reliably under varying loads and operating conditions, providing consistent and efficient conveying performance.

III. Excellent Chemical Resistance

In many industrial environments, conveyor belts are exposed to a wide range of chemicals, solvents, and corrosive substances. PVC whole core elevator belts offer excellent resistance to these harsh chemicals, making them suitable for use in industries such as chemical processing, food and beverage, and pharmaceuticals.

The PVC material forms a protective barrier that prevents corrosive agents from penetrating the belt's structure. This not only protects the belt itself but also ensures that the conveyed materials remain uncontaminated. Additionally, PVC's resistance to chemicals helps to maintain the belt's mechanical properties over time, prolonging its lifespan and reducing maintenance costs.

IV. Flexibility and Adaptability

PVC whole core elevator belts are highly flexible, allowing them to conform to various conveyor configurations and pulley diameters. This flexibility enables seamless integration into existing conveyor systems, minimizing the need for costly modifications or customizations.

Moreover, PVC belts can be easily modified to meet specific application requirements. They can be fabricated with different surface textures, colors, and reinforcements to suit particular conveying needs. For example, a textured surface can enhance traction and prevent slippage, while a colored belt can facilitate easy identification and tracking of materials.

V. Low Maintenance Requirements

Compared to other types of elevator belts, PVC whole core belts require minimal maintenance. Their durable construction and resistance to wear and tear mean that they are less prone to damage and degradation. Regular cleaning and inspection are usually sufficient to keep the belt in optimal condition.

In the event of minor damage, PVC belts can often be repaired quickly and easily using standard repair kits. This reduces downtime and ensures that production can continue with minimal disruption. Additionally, the smooth surface of PVC belts facilitates easy cleaning, further simplifying maintenance procedures.

VI. Cost-Effectiveness

Despite their numerous advantages, PVC whole core elevator belts are often more cost-effective than alternative options. The initial investment in PVC belts may be lower compared to some high-performance materials. Furthermore, their extended lifespan and low maintenance requirements translate into significant long-term savings.

The reduced need for frequent replacements, repairs, and downtime directly impacts operational costs. By choosing PVC whole core elevator belts, businesses can optimize their conveyor systems' efficiency and productivity while minimizing expenses. This cost-effectiveness makes PVC belts an attractive option for businesses of all sizes, from small-scale operations to large industrial complexes.

VII. Environmental Friendliness

In today's environmentally conscious world, the sustainability of industrial materials is of utmost importance. PVC whole core elevator belts offer several environmental benefits that make them a responsible choice for businesses.

Firstly, PVC is a recyclable material. At the end of its service life, PVC belts can be recycled and repurposed, reducing waste and conserving natural resources. This aligns with the principles of circular economy and helps businesses minimize their environmental footprint.

Secondly, the durability and longevity of PVC belts contribute to resource conservation. By lasting longer and requiring fewer replacements, PVC belts reduce the demand for raw materials and energy-intensive manufacturing processes associated with producing new belts.

Lastly, the low maintenance requirements of PVC belts also have environmental implications. With less frequent cleaning and repair, there is a reduction in the consumption of cleaning agents, water, and other resources. This further enhances the eco-friendliness of PVC whole core elevator belts.

VIII. Versatility in Applications

PVC whole core elevator belts find applications across a wide range of industries due to their versatility. Some of the common sectors where these belts are extensively used include:

Mining and Quarrying: In mining operations, PVC belts are employed for transporting ores, coal, and other bulk materials vertically or at steep inclines. Their high tensile strength and load-bearing capacity make them ideal for handling heavy loads in harsh mining environments.

Construction: During construction projects, PVC belts are utilized for conveying building materials such as cement, sand, and aggregates. Their flexibility and adaptability allow them to be easily integrated into temporary conveyor systems set up on construction sites.

Manufacturing: In manufacturing facilities, PVC belts are used for various material handling tasks, including the transportation of finished products, components, and packaging materials. Their resistance to chemicals and abrasion ensures reliable performance in diverse manufacturing processes.

Food and Beverage: The food and beverage industry requires conveyors that meet strict hygiene and safety standards. PVC belts, with their smooth surfaces and ease of cleaning, are well-suited for handling food products, beverages, and packaging materials in this sector.

Logistics and Warehousing: In logistics and warehousing operations, PVC belts are employed for sorting, transporting, and stacking goods. Their versatility and reliability make them an essential component of efficient material handling systems in warehouses and distribution centers.

IX. Conclusion

PVC whole core elevator belts offer a multitude of advantages that make them a preferred choice for industrial conveyance systems. Their enhanced durability, superior tensile strength, excellent chemical resistance, flexibility, low maintenance requirements, cost-effectiveness, environmental friendliness, and versatility in applications collectively contribute to their widespread adoption across various industries.

By investing in PVC whole core elevator belts, businesses can benefit from improved operational efficiency, reduced downtime, and long-term cost savings. Moreover, the environmental benefits associated with PVC belts align with the growing emphasis on sustainability in industrial practices.

As technology continues to advance and industries evolve, the demand for reliable and efficient conveyor systems will only increase. PVC whole core elevator belts are well-positioned to meet these demands, providing a robust and versatile solution for material handling challenges in the modern industrial landscape.

Related News