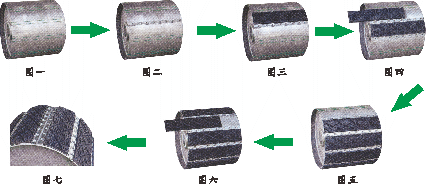

Roller cover inserts

Classification:

Keywords:Conveyor | Lifting belt | Dustpan

Inquiry

Product description

Basic Product Features and Advantages

1. Strong transmission friction: the surface of the diamond and Z-shaped groove structure, greatly improving the transmission friction between the drum and the belt, the belt running to obtain greater traction, improve transmission efficiency and reduce belt slippage.

2. Long service life: high elasticity and wear-resistant rubber material is used, and the fixing method is tight and reliable, which prolongs the service life of the roller.

3. Convenient installation and maintenance: when installing, there is no need to outsource laminating processing, shortening the processing cycle and saving the comprehensive cost of laminating; when repairing the laminating, the roller does not need to be disassembled, and can be quickly replaced on the spot, which reduces the downtime, improves the production efficiency and reduces the maintenance cost.

4. Good self-cleaning: the installation grooves between the double character pattern and the rubber-coated inserts are conducive to the discharge of inclusions between the belt and the drum to ensure smooth running of the belt without deflection and to prolong the life of the belt.

Excellent heat dissipation: The installation grooves between the double pattern and the overmoulded inserts provide good ventilation and heat dissipation, reducing the surface temperature of the belt and the head pulley.

Rubber properties

Rubber Properties: General purpose: Strong abrasion resistance, oil resistance, anti-static properties, widely used in general grain elevation and belt conveying equipment;

Flame-retardant: Strong wear-resistant, flame-retardant, oil-resistant, anti-static properties, in line with the safety requirements of underground coal mines;

Special performance can be customised according to user requirements.

Insert specification model: 1830mm(L)×139mm(W)×15mm(Thickness)

package

The roller blank diameter is determined:

According to the customer's drive roller design outer diameter and the selection of the determined specifications of the rubber-coated insert, minus 2 times the thickness of the rubber-coated insert for the roller blank diameter.

Product packages are identified:

According to the drum blank diameter and drum length provided by the customer, provide the customer with a matching programme to meet the requirements of static balance, the number of inserts for each head wheel = drum diameter (mm) x 3.14/160 before coating, if the number of inserts rows have a residual decimal, the remaining arc length can be divided equally by adopting the method of using two single-side strips instead of one double-side strips.

The rollers have a drum shape requirement:

If the blank is drum-shaped, wait for the rubber-coated inserts to be moulded; if the length of the blank is less than 750mm, it is recommended that the middle part of the drum should be appropriately padded according to the requirements of the drum; if the length of the blank is greater than or equal to 750mm, it is recommended that the drum be moulded into a drum when rubber-coated inserts are selected for the parallel drum.

Prev

Next

Prev

Next

Product Application

Processing Industry

Suitable for flour, feed, rice, corn processing, miscellaneous grain processing, oil and grease processing, grain drying and so on.

Warehousing Industry

Suitable for grain storage, granaries and harbour terminals, etc.

Machinery Industry

Suitable for flour, rice, feed, grain drying, etc.

Inquiry