What are roller cover inserts and strips used for?

Roller cover inserts and strips are essential components in various industries, playing a crucial role in ensuring the smooth and efficient operation of machinery and equipment. These components are designed to provide a durable and reliable surface for rollers, which are used in a wide range of applications, from printing and packaging to manufacturing and construction.

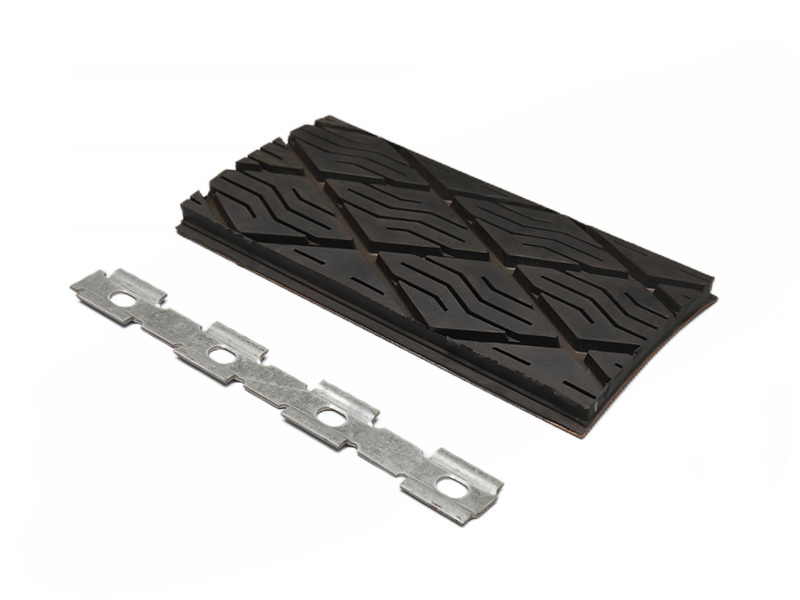

Roller cover inserts are typically made from high-quality materials such as rubber, polyurethane, or silicone, and are designed to fit snugly onto the surface of a roller. They are available in a variety of thicknesses, densities, and hardness levels, allowing them to be customized to meet the specific needs of different applications. The primary function of roller cover inserts is to provide a protective layer between the roller and the material being processed, preventing damage to both the roller and the material.

One of the main advantages of using roller cover inserts is their ability to reduce wear and tear on rollers. In many industrial applications, rollers are subjected to constant friction and pressure, which can cause them to wear down quickly. By using roller cover inserts, the wear and tear on the roller is significantly reduced, extending its lifespan and reducing the need for costly repairs or replacements.

Another benefit of roller cover inserts is their ability to improve the quality of the finished product. In industries such as printing and packaging, the surface of the roller can have a direct impact on the quality of the printed image or the seal of the package. By using high-quality roller cover inserts, manufacturers can ensure that their products meet the highest standards of quality and consistency.

Roller cover strips, on the other hand, are used to reinforce the edges of rollers, providing additional strength and durability. They are typically made from the same materials as roller cover inserts and are designed to fit snugly around the edge of the roller. Roller cover strips are particularly useful in applications where the roller is subjected to high levels of stress or where there is a risk of the roller becoming misshapen or damaged.

One of the main advantages of using roller cover strips is their ability to prevent the roller from becoming misshapen or damaged. In many industrial applications, rollers are subjected to constant pressure and stress, which can cause them to become misshapen or damaged over time. By using roller cover strips, the risk of the roller becoming misshapen or damaged is significantly reduced, ensuring that the roller remains in good condition and continues to operate efficiently.

Another benefit of roller cover strips is their ability to improve the overall performance of the roller. By providing additional strength and durability, roller cover strips can help to improve the roller's ability to withstand the rigors of industrial applications, ensuring that it continues to operate at peak performance levels.

In addition to their functional benefits, roller cover inserts and strips also offer a number of practical advantages. For example, they are relatively easy to install and remove, making it simple to replace them when they become worn or damaged. They are also available in a wide range of sizes and shapes, making it easy to find the perfect fit for any roller.

When selecting roller cover inserts and strips, it is important to consider a number of factors, including the type of material being processed, the operating conditions of the machinery, and the desired level of performance. By taking these factors into account, manufacturers can ensure that they select the right roller cover inserts and strips for their specific needs, ensuring that their machinery operates efficiently and effectively.

In conclusion, roller cover inserts and strips are essential components in many industrial applications, providing a durable and reliable surface for rollers and helping to improve the overall performance and efficiency of machinery. By understanding the benefits and applications of these components, manufacturers can make informed decisions about which roller cover inserts and strips are best suited to their specific needs, ensuring that their machinery operates at peak performance levels and delivers high-quality results.

Related News