What are the key factors in choosing roller cover inserts and strips?

Key Factors in Choosing Roller Cover Inserts and Strips

Selecting the right roller cover inserts and strips is a critical decision in various industrial, commercial, and manufacturing processes. These components play a vital role in ensuring efficiency, precision, and durability in applications such as painting, coating, laminating, and material handling. The wrong choice can lead to suboptimal performance, increased maintenance costs, and reduced productivity. To make an informed selection, several key factors must be carefully evaluated, including material composition, hardness and density, size and compatibility, operational environment, and maintenance requirements. Understanding these elements ensures that the chosen roller cover inserts and strips meet the specific demands of the application while maximizing performance and longevity.

1. Material Composition

The material of roller cover inserts and strips is one of the most fundamental considerations, as it directly influences durability, chemical resistance, and suitability for specific applications. Common materials include polyurethane, rubber, silicone, nitrile, and specialized composites, each offering distinct advantages depending on the operational requirements.

Polyurethane is widely favored for its exceptional abrasion resistance, flexibility, and ability to maintain shape under high pressure. It is often used in applications requiring precise finishes, such as high-gloss coatings or delicate material handling. Rubber, particularly natural or synthetic variants, provides excellent grip and elasticity, making it suitable for conveying or compressing materials. However, rubber may degrade faster under harsh chemicals or extreme temperatures compared to polyurethane.

Silicone is preferred in high-temperature environments due to its heat resistance and non-reactive properties. It is commonly used in food processing, medical, or baking industries where hygiene and temperature stability are critical. Nitrile offers superior resistance to oils, fuels, and solvents, making it ideal for applications involving petroleum-based products. Specialized composites, such as those reinforced with fiberglass or ceramic particles, provide enhanced durability for heavy-duty applications, such as mining or steel processing.

Selecting the appropriate material requires an analysis of the substances the roller will contact (e.g., paints, adhesives, chemicals) and the operational stresses (e.g., friction, heat, pressure). A mismatch in material properties can lead to premature wear, contamination, or operational failures.

2. Hardness and Density

The hardness and density of roller cover inserts and strips significantly impact their performance in terms of grip, pressure distribution, and material transfer. Hardness is typically measured in durometers (Shore A or Shore D scales), with lower values indicating softer materials and higher values representing harder, more rigid compositions.

Softer inserts (lower durometer) are preferred when a gentle grip or even pressure distribution is required, such as in printing, laminating, or delicate coating applications. They conform well to uneven surfaces, reducing the risk of marking or damaging the substrate. However, excessively soft materials may wear out quickly under high-pressure conditions or fail to maintain consistent pressure.

Harder inserts (higher durometer) are used in applications demanding durability and precise material transfer, such as heavy-duty printing, metal rolling, or high-tension conveying. They resist deformation under stress but may lack the flexibility needed for delicate operations. The optimal hardness depends on the balance between grip, wear resistance, and the nature of the materials being processed.

Density, closely related to hardness, affects the roller’s ability to absorb and distribute force. High-density inserts provide better resistance to compression and wear but may reduce flexibility. Conversely, lower-density materials offer more give but may compress unevenly over time. Evaluating the required hardness and density ensures that the roller cover performs efficiently without compromising longevity.

3. Size and Compatibility

Proper sizing and compatibility with existing roller systems are essential to ensure seamless integration and optimal performance. Roller cover inserts and strips must match the dimensions of the roller core, including diameter, width, and groove specifications (if applicable).

Diameter and width must align with the machinery’s design to prevent slippage, uneven pressure, or mechanical misalignment. An incorrectly sized insert can lead to operational inefficiencies, such as inconsistent coating thickness or material misfeeding. Additionally, the thickness of the insert affects the overall hardness and flexibility of the roller cover; thicker covers may provide greater durability but could alter the roller’s performance characteristics.

Compatibility with mounting systems is another critical factor. Some rollers require specific adhesives, mechanical fasteners, or heat-shrink fittings to secure the inserts. Ensuring that the chosen inserts and strips are compatible with the existing roller assembly simplifies installation and reduces the risk of premature detachment or damage.

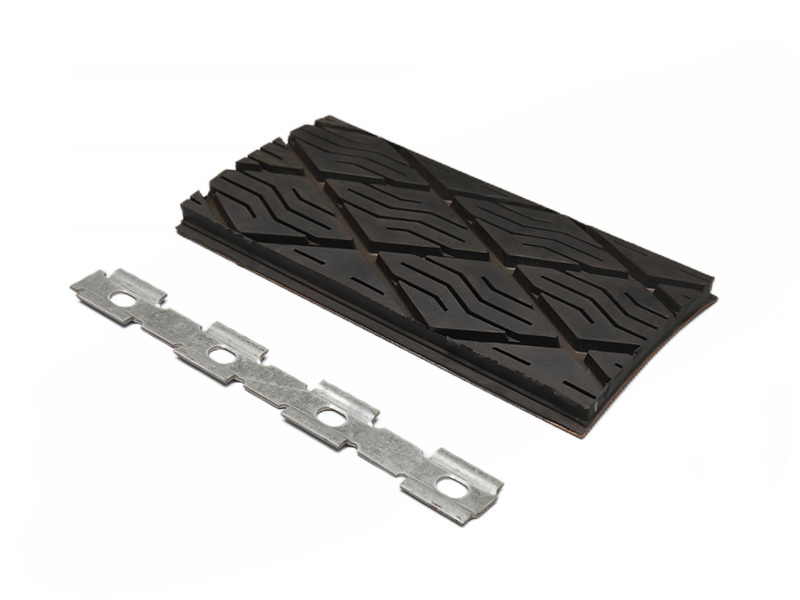

Furthermore, the surface texture of the insert (e.g., smooth, ribbed, or patterned) should align with the application’s requirements. Smooth surfaces are ideal for uniform material transfer, while textured surfaces enhance grip or facilitate specific finishing effects.

4. Operational Environment

The environment in which the roller operates profoundly influences the selection of inserts and strips. Factors such as temperature extremes, exposure to chemicals, moisture, and abrasive materials must be carefully assessed.

Temperature resistance is crucial in applications involving extreme heat or cold. For instance, silicone or high-temperature polyurethane is necessary for operations in baking ovens, drying chambers, or cryogenic environments. Materials that degrade under thermal stress can lead to warping, cracking, or loss of functionality.

Chemical exposure requires careful material selection to prevent swelling, corrosion, or breakdown. For example, nitrile or Viton-based inserts are suitable for oil and solvent resistance, while fluoropolymer coatings may be needed for highly corrosive chemicals.

Moisture and humidity can affect material integrity, particularly in outdoor or washdown environments. Water-resistant or antimicrobial materials may be required to maintain performance and hygiene.

Abrasive conditions, such as mining, woodworking, or metal processing, demand inserts with high abrasion resistance, such as polyurethane blends or ceramic-reinforced composites. Failure to account for environmental factors can result in rapid wear, frequent replacements, and downtime.

5. Maintenance and Longevity

The ease of maintenance and expected lifespan of roller cover inserts and strips are critical considerations for cost-effectiveness and operational efficiency. Some materials require regular cleaning, lubrication, or replacement, while others are designed for extended use with minimal upkeep.

Ease of replacement is a key factor in minimizing downtime. Inserts that can be quickly swapped without disassembling the entire roller system save time and labor costs. Additionally, some materials are self-cleaning or resistant to buildup, reducing the need for frequent maintenance.

Expected wear life varies based on material composition and operational conditions. High-quality polyurethane or ceramic-enhanced inserts may last significantly longer than standard rubber in abrasive environments. Evaluating the total cost of ownership—including initial purchase price, maintenance, and replacement frequency—ensures that the most economical and efficient option is selected.

Conclusion

Choosing the right roller cover inserts and strips involves a comprehensive evaluation of material properties, hardness, size, environmental factors, and maintenance requirements. By carefully considering these key factors, businesses can optimize performance, reduce operational risks, and extend the lifespan of their roller systems. Whether for precision coating, heavy-duty material handling, or sensitive material processing, the right selection ensures efficiency, reliability, and cost-effectiveness in any application.

Related News