What are the unique features of pvc whole core elevator belts?

1. Introduction

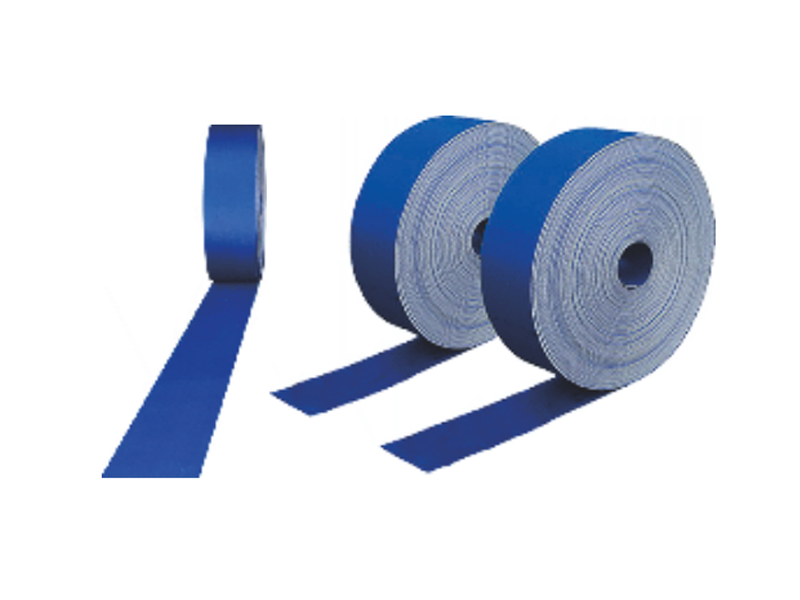

In the realm of industrial and commercial applications, elevator belts play a crucial role in ensuring the smooth and efficient movement of goods and people. Among the various types of elevator belts available, PVC Whole Core Elevator Belts have emerged as a popular choice due to their unique features and superior performance. This article aims to explore the distinct characteristics that set PVC Whole Core Elevator Belts apart from other alternatives.

2. Material Composition and Durability

2.1 High-Quality PVC Material

PVC Whole Core Elevator Belts are made from high-quality polyvinyl chloride (PVC). PVC is a versatile synthetic plastic polymer known for its excellent chemical resistance, durability, and weatherability. The use of PVC in the construction of elevator belts provides several advantages. Firstly, it offers resistance to a wide range of chemicals, including acids, alkalis, and solvents. This makes the belts suitable for use in various industrial environments where they may be exposed to different substances.

2.2 Reinforced Core Structure

The "whole core" design of these elevator belts refers to the presence of a strong and continuous core material, typically made of high-strength synthetic fibers or steel cords. This reinforced core provides enhanced tensile strength and load-bearing capacity. The core acts as the backbone of the belt, preventing it from stretching or breaking under heavy loads. As a result, PVC Whole Core Elevator Belts can handle significant weights and are ideal for applications where durability and strength are essential.

2.3 Longevity and Wear Resistance

PVC Whole Core Elevator Belts are designed to withstand the rigors of continuous use. The PVC material has a high resistance to abrasion, which means that the belts can endure friction and wear over time without significant deterioration. This wear resistance extends the lifespan of the belts, reducing the frequency of replacements and maintenance costs. In addition, the belts are less prone to cracking, fraying, or other forms of damage, ensuring reliable performance even in harsh operating conditions.

3. Performance Characteristics

3.1 Smooth and Quiet Operation

One of the standout features of PVC Whole Core Elevator Belts is their ability to provide smooth and quiet operation. The smooth surface of the PVC material reduces friction between the belt and the elevator components, resulting in a quieter ride. This is particularly important in commercial and residential buildings where noise levels need to be kept to a minimum. The smooth operation also helps to prevent damage to the goods being transported, ensuring their safety and integrity.

3.2 High Tensile Strength and Load Capacity

As mentioned earlier, the reinforced core structure of PVC Whole Core Elevator Belts gives them excellent tensile strength and load capacity. These belts can handle heavy loads without sagging or stretching, ensuring the efficient movement of goods. The high tensile strength also allows for the use of smaller pulleys and motors, reducing the overall size and cost of the elevator system. In industrial applications, where large and heavy items need to be transported, PVC Whole Core Elevator Belts are an ideal choice.

3.3 Resistance to Environmental Factors

PVC Whole Core Elevator Belts are highly resistant to environmental factors such as moisture, temperature variations, and UV radiation. This makes them suitable for use in a wide range of applications, including outdoor elevators, food processing facilities, and pharmaceutical plants. The resistance to moisture prevents the growth of mold and mildew, ensuring the hygiene and safety of the elevator system. The ability to withstand temperature variations means that the belts can operate effectively in both hot and cold environments without losing their performance characteristics.

4. Safety Features

4.1 Non-Slip Surface

The surface of PVC Whole Core Elevator Belts is designed to provide excellent traction, reducing the risk of slippage. This is crucial for the safe operation of the elevator, especially when transporting heavy or bulky items. The non-slip surface ensures that the goods remain securely in place during transit, preventing accidents and damage. In addition, the non-slip property also enhances the safety of passengers in passenger elevators, providing a more secure and comfortable ride.

4.2 Fire Resistance

Fire safety is a top priority in any building or industrial facility. PVC Whole Core Elevator Belts are often treated with fire-resistant coatings or made from materials with inherent fire resistance properties. This helps to prevent the spread of fire in the event of an emergency, providing valuable time for evacuation and firefighting efforts. Some PVC elevator belts are also self-extinguishing, meaning that they will stop burning once the source of the fire is removed.

4.3 Anti-Static Properties

In certain applications, such as in the electronics industry or flammable environments, the build-up of static electricity can be a serious safety hazard. PVC Whole Core Elevator Belts can be designed with anti-static properties to prevent the accumulation of static charges. This reduces the risk of electrical shocks and the ignition of flammable materials, ensuring the safety of both personnel and equipment.

5. Customization Options

5.1 Various Widths and Thicknesses

PVC Whole Core Elevator Belts are available in a wide range of widths and thicknesses to suit different application requirements. The width of the belt determines the load-carrying capacity, while the thickness affects its durability and resistance to wear. Manufacturers can customize the dimensions of the belts based on the specific needs of the customer, ensuring optimal performance and efficiency.

5.2 Different Surface Coatings

To enhance the performance and appearance of the elevator belts, PVC Whole Core Elevator Belts can be coated with various materials. For example, a smooth and glossy coating can be applied for a more professional look, while a textured coating can provide additional traction. Some coatings also offer additional protection against abrasion, chemicals, or UV radiation, further extending the lifespan of the belts.

5.3 Custom Printing and Branding

In addition to functional customization, PVC Whole Core Elevator Belts can also be customized with printing and branding. This allows companies to display their logos, slogans, or other promotional messages on the belts, enhancing their brand visibility. Custom printing can also be used to provide important information such as safety instructions, load limits, or product details.

6. Maintenance and Cost-Effectiveness

6.1 Easy Maintenance

PVC Whole Core Elevator Belts are relatively easy to maintain. They can be cleaned with simple detergents and water, and any minor damages or wear can be easily repaired. The belts do not require extensive lubrication or special maintenance procedures, reducing the time and effort required for upkeep. Regular inspection and maintenance can help to ensure the long-term performance and safety of the elevator system.

6.2 Cost-Effective Solution

Despite their high-quality construction and performance, PVC Whole Core Elevator Belts are a cost-effective solution for many applications. The durability and longevity of the belts reduce the frequency of replacements, resulting in significant cost savings over time. In addition, the ease of maintenance and the availability of replacement parts further contribute to the cost-effectiveness of these belts.

7. Applications in Various Industries

7.1 Manufacturing and Warehousing

In manufacturing and warehousing facilities, PVC Whole Core Elevator Belts are used to transport raw materials, finished products, and inventory between different levels. The high load capacity and smooth operation of the belts make them ideal for handling heavy and bulky items, ensuring efficient production and storage processes.

7.2 Food and Beverage Industry

The food and beverage industry requires elevator belts that are hygienic, easy to clean, and resistant to moisture and chemicals. PVC Whole Core Elevator Belts meet these requirements, making them suitable for transporting food products, packaging materials, and equipment in food processing plants, restaurants, and supermarkets.

7.3 Pharmaceutical and Healthcare

In the pharmaceutical and healthcare industries, safety and hygiene are of utmost importance. PVC Whole Core Elevator Belts with their non-slip, fire-resistant, and anti-static properties are widely used in hospitals, pharmacies, and research laboratories to transport drugs, medical equipment, and supplies.

7.4 Mining and Construction

In mining and construction applications, PVC Whole Core Elevator Belts are used to transport heavy materials such as ore, coal, and construction equipment in mines and construction sites. The high tensile strength and durability of the belts make them suitable for the harsh and demanding conditions of these industries.

8. Conclusion

PVC Whole Core Elevator Belts offer a unique combination of features that make them an excellent choice for a wide range of applications. Their durability, performance, safety features, customization options, ease of maintenance, and cost-effectiveness make them a reliable and efficient solution for transporting goods and people. Whether in manufacturing, food processing, pharmaceuticals, or construction, PVC Whole Core Elevator Belts play a vital role in ensuring the smooth and safe operation of elevator systems. As technology continues to advance, we can expect further improvements and innovations in PVC Whole Core Elevator Belts, making them even more versatile and effective in meeting the evolving needs of various industries.

Related News