What makes pvc whole core elevator belts more durable than traditional options?

Introduction

Elevator belts are critical components in material handling systems, ensuring the safe and efficient vertical transportation of goods. Traditionally, elevator belts have been made from materials like rubber, fabric, or steel cords, but PVC (Polyvinyl Chloride) whole core elevator belts have emerged as a superior alternative due to their enhanced durability, strength, and resistance to wear and tear.

This article explores the key reasons why PVC whole core elevator belts outperform traditional belt materials, focusing on their construction, material properties, resistance to environmental factors, load-bearing capacity, and long-term cost efficiency.

1. Construction and Design Advantages

1.1 What is a PVC Whole Core Elevator Belt?

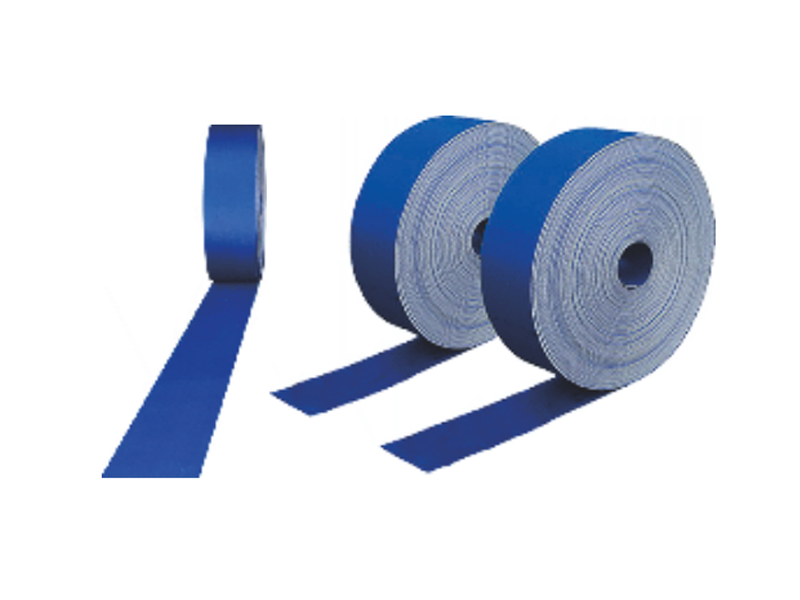

A PVC whole core elevator belt is constructed with a solid PVC core (instead of multiple fabric plies or steel cords) that is vulcanized or mechanically bonded to the belt’s surface. This design eliminates the need for multiple layers of fabric, which are common in traditional belts and prone to delamination.

Traditional Belts: Typically consist of multiple fabric plies (such as nylon, polyester, or cotton) with rubber coatings, or steel cord belts for heavy-duty applications.

PVC Whole Core Belts: Feature a single, solid PVC core that provides uniform strength, flexibility, and resistance to internal separation.

1.2 Elimination of Delamination Risks

One of the major weaknesses of traditional multi-ply belts is delamination, where the rubber layers separate from the fabric core due to friction, moisture, or heavy loads.

PVC whole core belts have no layers to separate, reducing the risk of sudden failure.

The solid PVC core ensures consistent tension distribution, preventing weak points that lead to tears or ruptures.

1.3 Flexibility and Formability

Traditional belts with fabric plies can become stiff over time, leading to cracking and reduced flexibility.

PVC whole core belts maintain high elasticity, allowing them to bend smoothly around pulleys without cracking or fatigue.

2. Material Properties: Why PVC is Superior

2.1 High Tensile Strength & Abrasion Resistance

PVC (Polyvinyl Chloride) is a synthetic polymer known for its exceptional tensile strength, meaning it can withstand high pulling forces without breaking.

Compared to rubber or fabric belts, PVC whole core belts resist abrasion much better, making them ideal for rough or abrasive materials (e.g., sand, gravel, or metal parts).

2.2 Chemical & Moisture Resistance

Traditional rubber belts degrade when exposed to oils, acids, or moisture, leading to swelling, cracking, or loss of grip.

PVC is inherently resistant to oils, fuels, and moisture, making it suitable for industrial environments (warehouses, chemical plants, food processing).

Unlike fabric belts that absorb water and weaken, PVC belts remain stable in wet conditions, preventing mold and degradation.

2.3 UV & Weather Resistance

Outdoor elevator systems (e.g., mining, construction) face UV radiation, extreme temperatures, and weathering.

PVC whole core belts have built-in UV stabilizers, preventing degradation from sunlight exposure.

Traditional rubber belts crack and harden under UV rays, shortening their lifespan.

3. Enhanced Load-Bearing Capacity & Durability

3.1 Higher Impact Resistance

Traditional belts (especially fabric-based ones) can tear or stretch when subjected to sudden impacts (e.g., heavy loads dropping onto the belt).

PVC whole core belts absorb shocks better, reducing the risk of puncture damage or belt stretching.

3.2 Better Grip & Traction

Many traditional belts rely on rubber coatings for grip, which can wear off over time.

PVC whole core belts have a textured or patterned surface (molded directly into the PVC), providing consistent traction without peeling.

3.3 Resistance to Fatigue & Long-Term Wear

Fabric belts weaken over time due to repeated flexing, leading to cracks at the edges or ply separation.

PVC whole core belts maintain structural integrity even after millions of cycles, making them ideal for high-frequency elevator systems.

4. Maintenance & Long-Term Cost Efficiency

4.1 Lower Maintenance Requirements

Traditional belts require frequent inspections for delamination, cracks, or wear.

PVC whole core belts have fewer failure points, reducing downtime and maintenance costs.

4.2 Longer Lifespan

While traditional belts may last 1–3 years in harsh conditions, PVC whole core belts can last 3–5 years or more with proper care.

Their resistance to abrasion, moisture, and chemicals means fewer replacements and lower long-term costs.

4.3 Easier Installation & Repair

PVC belts are lighter and easier to handle than heavy steel-cord or multi-ply belts.

If damaged, sections can be cut and rejoined without needing full belt replacement (unlike fabric belts that often require complete replacement).

5. Applications Where PVC Whole Core Belts Excel

Due to their durability, PVC whole core elevator belts are preferred in:

✔ Mining & Quarrying (handling rough, abrasive materials)

✔ Food Processing (resistant to cleaning chemicals and moisture)

✔ Warehousing & Logistics (high-frequency use without frequent failures)

✔ Construction & Heavy Industry (impact-resistant and long-lasting)

Conclusion: Why PVC Whole Core Elevator Belts Are the Future

PVC whole core elevator belts provide superior durability, strength, and resistance compared to traditional rubber, fabric, or steel-cord belts. Their solid PVC core eliminates delamination risks, enhances flexibility, and resists abrasion, chemicals, and moisture.

While traditional belts may have been the norm in the past, PVC whole core belts offer a longer lifespan, lower maintenance, and better performance in demanding environments—making them the most cost-effective and reliable choice for modern elevator systems.

For industries that prioritize efficiency, safety, and longevity, switching to PVC whole core elevator belts is a smart investment that pays off in reduced downtime and lower replacement costs.

Related News